- +1 (800) 826-0777

- VIRTUAL TOUR

- Mass Notification

- Threat Intelligence

- Employee Safety Monitoring

- Travel Risk Management

- Emergency Preparedness

- Remote Workforce

- Location and Asset Protection

- Business Continuity

- Why AlertMedia

- Who We Serve

- Customer Spotlights

- Resource Library

- Downloads & Guides

Prevent Workplace Slips, Trips, and Falls—8 Safety Tips

Mopping up a spill or double-checking a guardrail might seem like simple common sense, but slips, trips, and falls are the second most common cause of death at work. These are life-saving procedures. Keep reading for practical tips to prevent workplace accidents.

- Slip, Trip, and Fall Hazards Listed

- Clarifying OSHA Standards

- Prevent Workplace Slips, Trips, and Falls

These are familiar scenarios at home: slipping on a wet floor in the kitchen and tripping over a toy left out by the kids. While annoying, these accidents are typically minor hazards in the home. You might stub your toe, but rarely are there severe consequences.

In the workplace, it’s a different and far more serious story. Slips, trips, and falls account for over 200,000 workplace injuries per year. In 2020, nearly one in five accidents leading to missed work was due to a slip, trip, or fall. They’re also the second-leading cause of workplace fatalities.

As a safety leader, you’re responsible for your company’s duty of care and for providing a safe workplace . This blog post will examine common hazards leading to slips, trips, and falls and the steps you can take to minimize injury risks for your team.

Download Our Workplace Safety Checklist

What are slip, trip, and fall hazards in the workplace.

Accidents involving slips, trips, and falls are often grouped together. While they’re similar, it’s important to understand the distinction since they each have different causes and consequences.

Slips occur when someone’s footwear loses traction with the surface they’re on, causing a loss of balance. Under some circumstances, slipping can lead to a fall.

Trips happen when someone hits their foot or lower leg on an object. As their upper body continues moving forward while their lower body remains stationary, the person may lose their balance in the process.

Falls often result from slips or trips, but they can also happen on their own. For example, a worker on a ladder or scaffolding can lose their balance and fall without slipping or tripping. Falls are also possible on flat surfaces and can still cause serious injuries.

Once you understand the hazards that lead to each type of accident, you can identify and mitigate risks in your workplace. Here are some of the most common causes of slips, trips, and falls in the workplace:

Slip Hazards

- Spills of wet or dry substances

- The cleaning process during spill removal

- Employees rushing or not paying attention to workplace conditions, especially while carrying objects

- Slippery floor surfaces such as marble or laminate

- Wet surfaces

- Poor lighting that obscures hazards

- Inappropriate footwear for the environment

- Transitioning between different types of surfaces

Trip Hazards

- Objects or obstructions in walkways

- Uneven surfaces on flooring or concrete

- Cables, cords, and hoses that aren’t properly secured or organized

- Unmarked steps or ramps

- Irregular stairs or stairs without railings

- Carpet, rugs, or mats with wrinkles or lifted edges

Fall Hazards

- Improperly used or poorly maintained ladders

- Elevated surfaces without guardrails

- Floor and wall openings

- Working in elevated environments without a safety harness

- Ill-fitting or improperly used PPE, such as helmets and safety lines

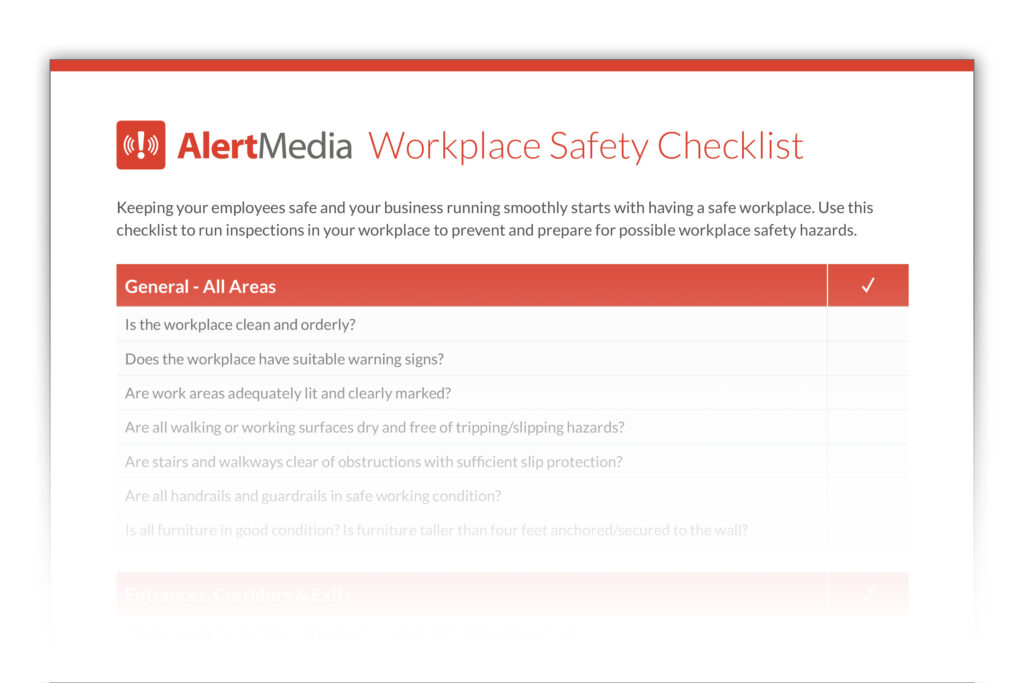

Preview the Workplace Safety Checklist

Are There OSHA Standards Related to Slips, Trips, and Falls?

Despite how common these injuries are, there is no specific OSHA standard on slips, trips, and falls. However, several OSHA rules indirectly address the same hazards.

The most important regulation to be aware of is 29 CFR 1910 Subpart D, which covers walking and working surfaces. OSHA updated the standard in 2017, introducing many upgrades to fall protection system requirements, improved employer-provided inspection guidelines, and a greater emphasis on safety training for employees.

For the construction industry, 29 CFR 1916 contains numerous fall-related regulations. Subpart M specifically addresses fall prevention, but other sections, such as Subpart L (scaffolds) and Subpart E (personal protective and lifesaving equipment), are also relevant. OSHA used 29 CFR 1916 as guidance when revising 29 CFR 1910, so the two guidelines now reflect many of the same OSHA violations .

As with any other workplace hazard or accident, OSHA recordkeeping requirements still apply in the event of a slip, trip, or fall incident. Internally, the reporting process is also an opportunity to review the details of the incident and determine how you can update your workplace safety policy to prevent similar accidents in the future.

How to Prevent Slips, Trips, and Falls in the Workplace

Many hazards that cause slips, trips, and falls are inevitable. However, injuries and accidents are not. To prevent slips, trips, and falls, train your employees to follow a three-step process:

- Recognize the hazard: Identify conditions that could lead to a slip, trip, or fall.

- Evaluate the hazard: Examine the situation and determine what level of risk it presents and who it affects.

- Control the hazard: Avoid the risk by removing the hazard (such as mopping up a spill) or implementing safety equipment and procedures (such as installing handrails on an elevated platform).

Here are eight workplace safety tips to prevent falls, trips, and slips.

1. Teach situational awareness

Since many causes of slips, trips, and falls are foreseeable, situational awareness in the workplace is one of the best preventative measures. Encourage your employees to pay attention to their surroundings and the risks they present:

- Look at walking surfaces for spills, obstacles, or other potential hazards

- Watch for signage that warns of increased hazards

- Be aware of conditions such as weather or time of day that might increase the risk of an accident

- Take shorter and more cautious steps on slippery surfaces

2. Encourage proper footwear

Like any other form of PPE, proper footwear can significantly reduce the risk of accidents. Research has found that slip-resistant shoes can reduce injury claims by 67% in environments with slippery work surfaces.

Employees should regularly inspect their shoes and make sure the soles aren’t worn out, as the lack of tread increases the danger of slipping. Additionally, anyone who works in conditions exposed to winter weather hazards should wear insulated boots. Cold temperatures can decrease muscle function, increasing the risk of slipping, tripping, or falling.

3. Utilize signage

Signage is an effective warning system for many workplace risks, but it can be especially effective in preventing slips, trips, and falls. There are two types of signs you can use to increase occupational safety:

- Temporary: Use warning signs while addressing a new hazard, such as cleaning up a spill, repairing a handrail, or replacing a ripped carpet. While temporary signage can help prevent injuries, you still need to address the actual hazard as quickly as possible.

- Permanent: For unavoidable hazards, such as slippery surfaces, a permanent sign can help warn employees to be careful. Use these sparingly, though, as it’s easy for people to ignore signs they see every day.

4. Keep floors clear and clean

Good housekeeping can help prevent most slips, trips, and falls. The details of keeping walking areas clean will vary widely by work environment, but there are a few common themes to encourage workplace safety:

- Report spills immediately, and warn nearby employees until someone can clean the contaminated surface

- Keep walkways clear of obstacles, loose objects, and anything that someone could trip over

- Place mats at entrances and exits so people can dry their shoes and avoid tracking water or other substances around the workplace

- Install handrails on stairways and elevated walkways

5. Apply non-slip mats and coatings

In some situations, keeping floors from becoming slippery is nearly impossible. Whether it’s liquid splashing or steam condensing, you must focus on mitigating the risk rather than avoiding it altogether.

For smaller or less demanding settings, non-slip mats can help employees maintain traction while walking around. In other cases, treating the floor with a permanent coating can help reduce slipping risks, even in the constant presence of liquids.

Who is at risk for slips, trips, and falls?

While all industries have some level of risk for a slip, trip, or fall, there are some industries where the risk is much higher, and the potential result could be much more dangerous. Here are some of the highest-risk industries:

- Construction

- Manufacturing

- Transportation/shipping/logistics

- Outdoor maintenance/groundskeeping

- Foodservice/hospitality

6. Ensure proper lighting

To identify slip, trip, and fall hazards, your employees need to be able to see their surroundings. Make sure that all of your work areas have proper lighting, especially in areas that are more prone to unsafe conditions.

While this can be a challenge in outdoor work environments, especially at night, it’s even more critical in those situations. Environmental conditions can lead to increased risks, and employees need to be able to see and avoid them. Adequate lighting should also extend to parking lots and walking areas around your facilities.

7. Develop safety programs

Your company’s safety plans and programs should include specific guidelines for preventing slips, trips, and falls. There are a few key topics to consider when developing these policies:

- The types of surfaces employees work and walk on and whether they present extra risks

- Seasonal or regional conditions that could heighten hazards, such as winter weather threats

- Specific OSHA regulations that apply to your workplace

- Potentially hazardous equipment training such as ladder safety

- Regular inspection plans to ensure your team is maintaining a safe work environment

- Policies to report hazards using your company’s two-way communication platform

- First aid training , so employees are prepared to respond safely should injuries occur

8. Provide Slips, Trips, and Falls Training

Lastly, training your employees to avoid slips, trips, and falls will help keep them safe. Provide specific guidance on the environments they’ll work in and the hazards they’ll face. For example, a slips, trips, and falls safety talk for food service workers should focus on wet floors and walking safely in crowded, fast-paced environments. Conversely, office workers could use extra reminders to watch for stray power cords and keep walkways clear of boxes, files, and other tripping hazards.

Working slips, trips, and falls into your safety topics for meetings is also helpful. Regular safety talks or safety moments are an excellent opportunity to remind your team about seasonal risks or update them on newly installed safety measures.

Don’t Let Your Safety Standards Slip

Slips, trips, and falls are some of the most common workplace injuries. Fortunately, you can usually prevent them with proper planning and safety measures.

By making slip, trip, and fall prevention a part of your company’s safety culture, you can ensure your employees are aware of their surroundings and ready to look out for each other’s safety. Enable them to report hazards easily, address risks quickly, and train them to avoid situations that are likely to cause injury.

With the right planning and prevention, even the most intense work environments can be as safe as a walk in the park.

More Articles You May Be Interested In

Workplace Safety Checklist

Please complete the form below to receive this resource.

Check Your Inbox!

The document you requested has been sent to your provided email address.

Cookies are required to play this video.

Click the blue shield icon on the bottom left of your screen to edit your cookie preferences.

Slip, Trip, and Fall Prevention for Healthcare Workers

December 2010, dhhs (niosh) publication number 2011-123.

According to the U.S. Bureau of Labor Statistics [2009], the incidence rate of lost-workday injuries from slips, trips, and falls (STFs) on the same level in hospitals was 38.2 per 10,000 employees, which was 90% greater than the average rate for all other private industries combined (20.1 per 10,000 employees). STFs as a whole are the second most common cause of lost-workday injuries in hospitals.

Slip, Trip, and Fall Prevention for Healthcare Workers pdf icon [PDF 979.73KB]

Follow NIOSH

Niosh homepage.

- Workplace Safety & Health Topics

- Publications and Products

- Contact NIOSH

Exit Notification / Disclaimer Policy

- The Centers for Disease Control and Prevention (CDC) cannot attest to the accuracy of a non-federal website.

- Linking to a non-federal website does not constitute an endorsement by CDC or any of its employees of the sponsors or the information and products presented on the website.

- You will be subject to the destination website's privacy policy when you follow the link.

- CDC is not responsible for Section 508 compliance (accessibility) on other federal or private website.

How to Conduct a Risk Assessment for Slips, Trips, and Falls

When was the last time you conducted a risk assessment at your facility for slips, trips and falls? Has it been more than a year? If so, you’re due for another assessment.

According to Jerry Chapman, Corporate Safety Manager at ITU AbsorbTech, once you’ve assessed your facility, it becomes a matter of sustainability. Any time you have a floor layout or traffic flow change, you should reassess. You should also reassess at least annually to look for changes or maintenance issues. Conduct your observations at different times of the day and year to account for shift changes and seasonal changes such as snow being tracked indoors.

What are Slips, Trips and Falls?

A slip results from too little friction between footwear and the walking surface, resulting in loss of balance. Common culprits include water, snow, mud, grease, oil, food, dust, powders, fresh wax, and poor housekeeping.

A trip occurs when the foot or lower leg comes in contact with an object or steps down and loses balance.

A fall can occur at the same level, or to a lower level and occurs when someone is off their center of balance.

Why conduct a facility assessment?

A facility assessment helps identify the location of high risk hazards. According to OSHA, the majority of general industry accidents are slips, trips, and falls. They cause 15% of all accidental deaths and are second only to motor vehicle accidents as a cause of fatalities. And most could have been prevented.

Slips, trips, and falls are regulated by OSHA and ANSI. 29 CFR 1910 Subpart D includes requirements for housekeeping, aisles, floor and wall openings, open-sided floors, stairways, railings, stairs, scaffolding and ladders. The requirements can be found on the OSHA web site .

In addition, ANSI has adopted standards for floor safety in partnership with the National Floor Safety Institute (NFSI). The B101.1 floor safety standard makes property owners accountable for the slip resistance of their walkways.

Slips, trips and falls can be costly to your company. According to the 2016 National Safety Council report, the average costs for a slip/fall incident was $31,788 for a knee injury, $26,357 for an ankle injury, and $24,964 for a foot or toe injury. This doesn’t include the cost of reduced productivity, training a replacement worker, OSHA fines, and increase in insurance premiums. There are also costs to the employee, including lost wages, pain, potential disability or emotional disorder, and even death.

Who should be involved in an assessment?

This is determined by your organizational structure, corporate culture, and style of safety management. For example, the culture at ITU AbsorbTech is team-based with group participation and engagement. All managers and their respective employees are involved in the process.

Other styles may be more authoritative or control-based. The style of safety management will determine how your assessment is conducted.

An Environmental Heath & Safety Manager may conduct the assessment, an insurance representative can advise, and outside vendors and consultants can offer third party advice in their respective area of expertise. For example, as a safety floor mat provider, our company conducts hundreds of facility assessments each year and can identify slip hazards often overlooked.

Areas to Assess

The first step in your assessment is to make a list of all the risk areas. The most common are:

- Level floors

- Raised surface (such as a mezzanine or boom lift)

- Parking Lot

What are the different ways to assess your facility?

Job safety analysis (jsa).

A job safety analysis is a systematic study of work prodedures or instructions to determine hazards created by unsafe hazards or conditions within in a job or task. This should be completed for any job that has high or serious accident frequency, is hazardous in nature, has a new or different tasks, is seasonal or temporary, or can cause pain or ergonomic risks. To conduct a JSA, identify all possible hazards or unsafe conditions, including slips, trips, and falls, pinched fingers, flygin debris, etc. Each hazard should be addressed with a corrective procedure, improved environment (such as a safety rail or PPE), and/or reduced frequency.

Observation

Past history/trend analysis, employee feedback, safety checklists.

OSHA provides a number of safety checklists located here : http://www.isri.org/safety-best-practices/isri-safety/isri-safety-resources/osha-resources/osha-inspection-checklist#.WG6nZFMrJEY

We put together a quick checklist for some of the common slip, trip and fall hazards to watch for.

Slips and Trips, and Falls Prevention Checklist

- Paved entrance cracking or uneven

- Ice, water, or mud tracked in from the outdoors

- Rumpled floor mats or carpet with curled edges

- Uneven transition from one surface to another

- Coffee spills

- Puddles by the water fountain

- Cafeteria sinks

- Spills near food vending areas

- Slick floor from polish or wax

- Open cabinets, files, or desk drawers

- Missing or uneven floor tiles

- Bathroom sinks or toilets leaking or overflowing

- Soap spills

- Puddles under air dryer or towel station

- Slick floor from mopping

- Chemicals, fluids that can be tracked, spilled, sprayed, dripped

- Leaking or dripping fluids in and around machinery

- Pallets or tools in gangways

- Protruding nails, splinters, holes, or loose boards

- Dusts, powers, granules, or plastic wrapping

- Obstructions in aisles and passageways

- Piled up items

- Uncovered hoses, cables, wires, or extension cords

Additional Checklists

OSHA provides checklists for the following areas regarding fall protection. Click on the link to view the checklist.

- Raised Surface : Fall protection on walking or working surfaces that are 6 feet or more above lower levels.

- Guardrails: Guardrail systems, personal fall arrest systems, or warning line systems.

- Controlled-access: Controlled-access zones, safety monitoring systems, covers, protection from falling objects, or fall protection plans are used.

Risk management

A facility assessment is an ongoing process. Along with the risk assessment comes the process of risk management and root cause analysis. In this stage, you will evaluate the conditions responsible for a hazard. Is it the environment? Poor lighting? Temperature? Air quality? Health condition of employees? Improper personal protective equipment or footwear? Poor housekeeping? Improper cleaning methods? Lack of signs or training? Lack of motivation?

A facility assessment provides a framework for risk analysis, but the process doesn’t end there. Here is a list of some of Jerry’s favorite safety resources to learn more:

- Safetycom: For tips on home and family

- KellerOnline.com : Subscription to this has been a great resource

- OSHA.gov/law-regs.html : Note if regulation number is highlighted it has links to directives/letters and interpretations

Jerry Chapman is the Corporate Safety Manager for ITU AbsorbTech. He is a certified safety professional that has helped ITU AbsorbTech achieve an 82% reduction in injury rates in the past 10 years (compared to previous 10 years) with an average incident rate at about half of the industry average. Jerry also played a role in helping ITU AbsorbTech win the Wisconsin Corporate Safety award in 2010, 2012, 2014, the Pennsylvania Governor’s Safety Award in 2012, and the Indiana Governor’s Workplace Safety Awar in 2012.

Related Posts

How Can Oil Leaking Machines Lead to Improved Operational Efficiency?

Best Reusable Spill Control Supplies for Manufacturing and the Three Cs of Spill Control

Solvent Management Best Practices for Printers

Requirements for First Aid Kits in the Workplace

Share this entry.

- Share on Facebook

- Share on Twitter

- Share on WhatsApp

- Share on LinkedIn

- Share by Mail

Company News

Helpful Links

An official website of the United States government.

Here’s how you know

The .gov means it’s official. Federal government websites often end in .gov or .mil. Before sharing sensitive information, make sure you’re on a federal government site.

The site is secure. The https:// ensures that you are connecting to the official website and that any information you provide is encrypted and transmitted securely.

Occupational Safety and Health Administration

- 中文(简体) (Chinese-Simplified)

- 繁體中文 (Chinese-Traditional)

- Kreyòl ayisyen (Haitian Creole)

- 한국어 (Korean)

- Español (Spanish)

- Filipino/Tagalog

- Tiếng Việt (Vietnamese)

- By Standard Number

- 1910.22 - General requirements.

- Part Number: 1910

- Part Number Title: Occupational Safety and Health Standards

- Subpart: 1910 Subpart D

- Subpart Title: Walking-Working Surfaces

- Standard Number: 1910.22

- Title: General requirements.

- GPO Source: e-CFR

Hazardous conditions on walking-working surfaces are corrected or repaired before an employee uses the walking-working surface again. If the correction or repair cannot be made immediately, the hazard must be guarded to prevent employees from using the walking-working surface until the hazard is corrected or repaired; and

[81 FR 82983, Nov. 18, 2016]

IMAGES

VIDEO

COMMENTS

Tailor this checklist to your workplace environment and use it when inspecting your workplace to: 1) Identify hazards that could cause workers to slip, trip or fall; and 2) Document actions needed to address the hazards identified. Slips, Trips, and Falls Inspection Checklist.

That means preventing slips, trips, and falls is an ongoing process that relies heavily on employees being able to recognize related hazards. What Are OSHA's Trip Hazard Regulations? OSHA's primary standard for slip, trip, and fall hazards is the General Industry Walking-Working Surface standard (29 CFR 1910 Subpart D, which includes §1910.21-30).

The checklist asks about hazards . found in each room of your home. For each hazard, the checklist tells you how to fix the problem. At the end of the checklist, you'll find other tips for preventing falls. "Making changes in our home to prevent falls is . good for us and for our granddaughter when she comes to visit." Check for. Safety ...

Use the checklist below to determine if there are slip, trip and/or fall hazards in your workplace. If you answer "yes" to any of the questions below there may be a slip, trip or fall hazard requiring immediate action. Curbs are properl y painted in a contrasting color to that of adjacent walkways RAMPS: YES NO N/A ACTION

PREVENTING SLIPS, TRIPS AND FALLS CHECKLIST Many people attribute falls to being clumsy or not paying attention, but many risk factors exist. Reduce your risk of slips, trips and falls: ... National Safety Council 1121 spring lake drive itasca, il 60143-3201 (800) 621-7619 nsc.org

Enhance safety practices by benchmarking the historical performance of the organization as well as addressing recurring safety concerns using the Analytics dashboard. To get you started, here are pre-made checklists and templates you can use for your slips, trips, and falls safety management processes: Slips, Trips, and Falls Checklist

walking or working surfaces. Ensure suitable mats are present at entrances. Install suitable drainage in floor surfaces. resistance of both surfaces similar. paper and gravel and remove algae or slime with a chlorine-based solution. Ensure suitable footwear is worn that meets an acceptable dress code.

Permanent: For unavoidable hazards, such as slippery surfaces, a permanent sign can help warn employees to be careful. Use these sparingly, though, as it's easy for people to ignore signs they see every day. 4. Keep floors clear and clean. Good housekeeping can help prevent most slips, trips, and falls.

Checklist memers et oe Slips, trips and falls are the No. 2 cause of nonfatal disabling injury in the workplace following overexertion. Fortunately, by being aware of our surroundings, slips, trips and falls are easily preventable. Reduce tripping hazards with these tips: Be aware of your surroundings

Slip, Trip, and Fall Prevention for Healthcare Workers. Español (Spanish) December 2010. DHHS (NIOSH) Publication Number 2011-123. According to the U.S. Bureau of Labor Statistics [2009], the incidence rate of lost-workday injuries from slips, trips, and falls (STFs) on the same level in hospitals was 38.2 per 10,000 employees, which was 90% ...

The Occupational Safety & Health Administration (OSHA) recently revised and published a final rule for walking-working surfaces and personal fall protection systems. Use this simple checklist to audit potential problem areas for common slip, trip, and fall hazards in your working environments.

This checklist is merely a guideline. It is neither meant to be exhaustive nor meant to be construed as legal advice. ... SLIP AND TRIP HAZARD . PREVENTION . Date: Review conducted by: Use this checklist to help identify common slip and trip hazards in your workplace and actions you can take to resolve them. Make sure you customize this ...

Slip, Trips & Falls Handout. maintains general industry regulations on walking/working surfaces that guard against hazards including clutter, protruding objects and wet conditions. These hazards can harm everyone in a facility, regardless of title or job responsibilities. Slips, trips, and falls cause nearly 700 fatalities per year and many ...

Rubberized flooring or rubber tile floor surfaces are stable, flush and free from slip, trip, and fall exposures. Yes No N/A. 13. Electrical cords are appropriately secured and/or covered with an OSHA approved electrical cord cover to protect cords and reduce trip and fall exposures. Yes No N/A.

Use checklists that highlight things to look for. Typical hazards fall into several major categories, such as those listed below; each workplace will have its own list: General housekeeping; Slip, trip, and fall hazards; Electrical hazards; Equipment operation; Equipment maintenance; Fire protection

Trips. The majority of trips are caused by obstructions in walkways. The rest are caused by uneven surfaces. Preventing these accidents is often simple and cost-effective. You need to get all three right (walkways, housekeeping and design and maintenance), to prevent tripping accidents.

Health and Safety Executive. Slips and trips. Hazard spotting checklist. This checklist will help you identify slip and trip hazards in your workplace and decide what action to take. It will be of benefit to anyone who assesses and manages slips and trips at work. The checklist provides examples of hazards that can be found in and around ...

The B101.1 floor safety standard makes property owners accountable for the slip resistance of their walkways. Slips, trips and falls can be costly to your company. According to the 2016 National Safety Council report, the average costs for a slip/fall incident was $31,788 for a knee injury, $26,357 for an ankle injury, and $24,964 for a foot or ...

The Online Assessment will guide you through filling out your TRiPS worksheet step by step. It will assist you in calculating your travel route times and distances, it will provide you the risks associated with your trip, and it will automatically format your TRiPS Assessment into a PDF and send it to whatever email address you specify. Please ...

1910.22 (a) (1) All places of employment, passageways, storerooms, service rooms, and walking-working surfaces are kept in a clean, orderly, and sanitary condition. 1910.22 (a) (2) The floor of each workroom is maintained in a clean and, to the extent feasible, in a dry condition. When wet processes are used, drainage must be maintained and, to ...

A 12-Point Playground Safety Checklist 1. PROPER SURFACING The surface under and around playground equipment should be soft enough to ... Surfacing should be checked routinely for trip hazards, kick-out (displacement), debris and proper drainage. When selecting playground surfacing it is important to ensure your surfacing meets the requirements ...

Surfaces— Self Inspection Checklist" found in Appendix C. The results of this inspection will be used to: • Eliminate or control obvious hazards Target specific work areas for more intensive investigation • Assist in revising the checklists used during • Evaluate the effectiveness of our slip, trip and fall prevention program

Field trip safety checklist. The key to safety on field trips is advance planning. All field trip leaders must be aware of the need for attention to safety during field trip planning. Field trip safety is a shared responsibility. Such excursions may expose participants to a variety of hazards. The school has a responsibility to attempt to ...

hazards was developed based on the recommendations by Drury and Dempsey (2012), which indicated that regulations, standards, and guidelines can be an excellent source of information to identify hazards when developing audits and checklists. Both mining-specific and general industry regulations in the U.S. along with common standards and guidelines