Rings and travellers

Running performance at its best..

Rings and travellers are the dominant elements in the ring-spinning process. Key to success is the reduction of the friction coefficient to the lowest level possible. At this point you will get the perfect balanced spinning geometry – that means the spinning tension is on a constant balanced level.

The reduction of friction will be achieved if the rings and travellers establish a symbiosis. Therefore we focused on the ideal combination of rings and travellers. The aspired ideal friction stands for:

- Higher traveller speed

- Lower working temperature

- Extended ring and traveller life time

- Avoidance of yarn tension peaks

- Better yarn quality (reduction of hairiness)

- Reduction of end breaks

Furthermore the ideal friction strikes the balance between:

- Traveller drive angle to ring

- Traveller weight

- Traveller and ring geometry

- Traveller and ring coating

- Ring positioning

- No running-in time

- Consistent smooth running behaviour

- Perfect roundness, no vibration during spinning

- No variations in ring sizes

- High speed spinning for all fiber materials, yarn types and vast yarn count ranges

- Smart traveller design with specific coatings for an optimized balance between traveller speed, life time and yarn quality

- Universal suitability

Smart doffing.

Find out more about our products. Here we provide you with all the relevant documents for download in PDF format.

Brochure_Rings&Travellers_EN

Should you have questions about our products or require additional guidance, kindly get in touch with your local contact person. As your partner, we pride ourselves in providing expert and swift support.

Ring Travelers

Long running times and high speed for outstanding performance.

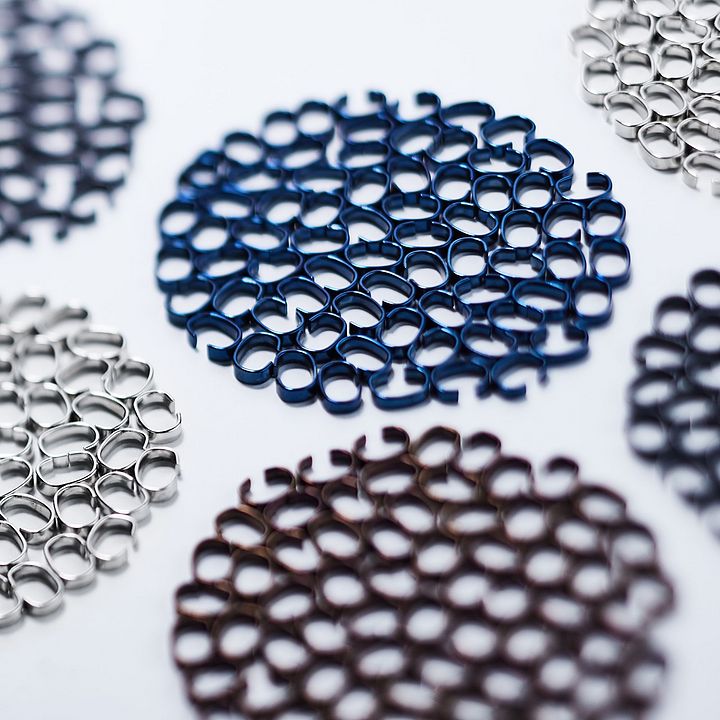

Bräcker offers travelers for short- and long-staple spinning. These Swiss-made travelers demonstrate unfailing consistency with the narrowest tolerances.

Ring travelers for short-staple spinning

The best performance can only be reached using the best traveler. With various shapes, wire cross-section, weights and finishes, Bräcker’s travelers cover any requirements, even the most challenging ones.

Ring travelers for long-staple spinning

Made of first grade materials, Bräcker’s travelers for long-staple spinning showcase excellent running characteristics, resulting in longer lifetime and higher productivity.

Ring Travelers for Short-Staple Spinning

- High productivity

- Maximum production consistency

- Optimum running characteristics

- Universal applicability

As one of the key components in ring and compact spinning, Bräcker offers travelers in various shapes and finishes to fit any requirements.

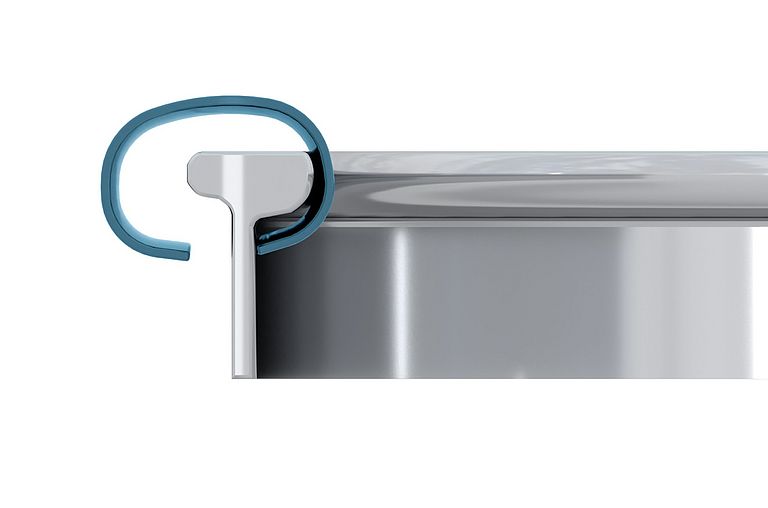

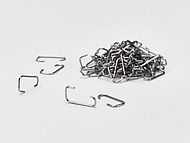

C-shaped travelers for T-flange applications

The contact area to the ring surface is punctiform. The traveler aligns itself optimally to the load during operation.

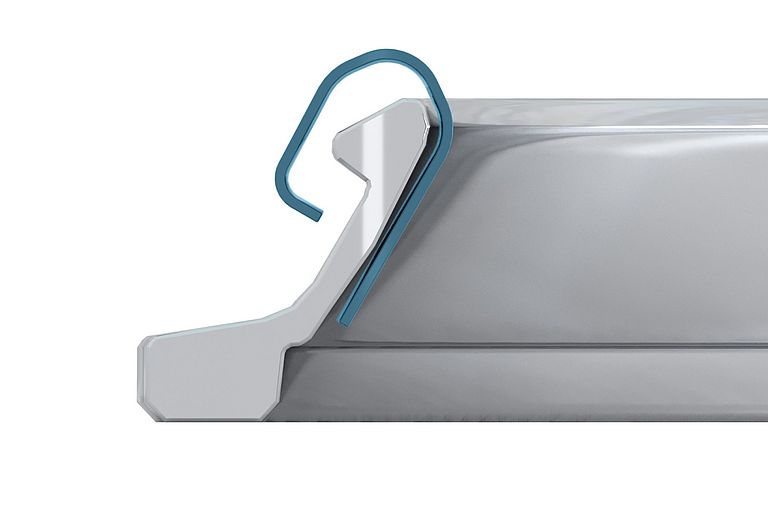

SFB travelers for ORBIT rings

There is a larger contact surface between the ring and the traveler and the traveler has a larger yarn passage. This results in higher heat dissipation and greater stability when the traveler is running.

SAPHIR travelers have been exposed to a special diffusion process. The enrichment components are present on the surface and throughout the traveler body. This guarantees consistently good running conditions over the entire lifespan of the traveler.

Highlights :

- For all fiber types and yarn counts

- For both, regular operation and running-in

The improved gliding characteristics make it possible to increase the spindle speed by up to +1 000 rpm and prolong the lifespan of the traveler by as much as +50%. Furthermore, the running-in period is considerably reduced.

- For cotton yarns, including compact

- For high spindle and traveler speeds

STARLET travelers are finished with a fine and compact nickel layer. Low friction values in the yarn passage prevent fiber damage and ensure good gliding characteristics after the traveler is changed.

- For demanding environmental conditions

- For man-made fibers and blends

STARLETplus

Processing aggressive fibers can lead to cutting marks in the yarn path. The time it takes for such cutting marks to appear sets the benchmark for traveler quality.

- For viscose and cotton-viscose blends

- For polyester and dyed fibers

A traveler designed to meet the requirements of spinning mills that work with man-made fibers.

Highlights:

- For man-made fibers, blends and core yarns

- Good gliding characteristics

The PYRIT treated traveler features unbeatable performance in terms of service life and speed. It can last up to three times longer than a regular traveler.

- For all fiber types

- No cutting-in in the yarn path

- Extended traveler replacement intervals

The innovative ceramic coating gives the traveler a service life of over 1 000 hours.

- Lower machine downtime

- For highly automated spinning mills with long machines

- For installations with potential for high speeds

Tools for ring travelers

For a fast, precise and easy insertion/removal of travelers, Bräcker offers useful tools.

- English PDF / 2 MB

- Spanish PDF / 2 MB

Bräcker always wants to answer queries quickly and competently.

- 864.542.8037

- Textile Products

- Industrial Vacuum Systems

- Filtration Products

- Viscose Technology & Air Purification

- Vario Modular Hose

- Shredding Systems

- Industrial Automation

- Commitment to Quality

- Yarn Processing

Rings & Travellers

Product range.

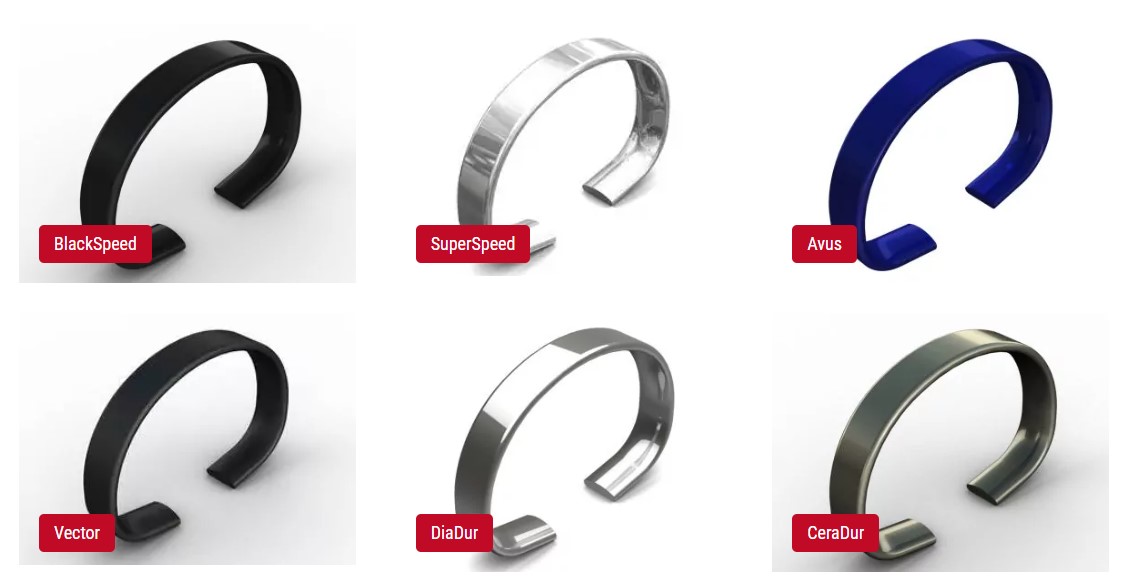

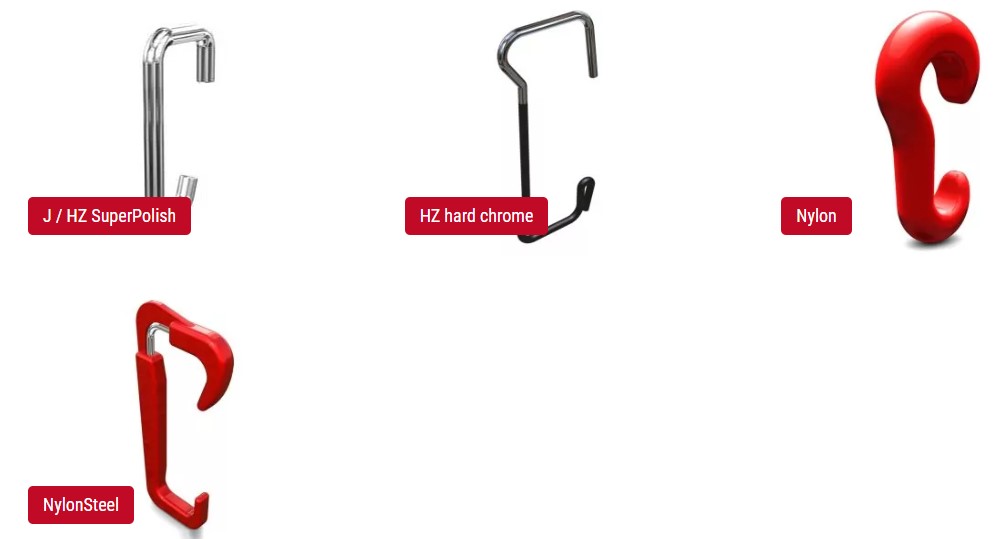

Our production program includes:

- High-performance spinning rings for ring spinning and twisting machines in all common technical designs for achieving the highest spindle speeds with excellent service lives.

- Precisely fitted ring travellers, made of steel and nylon, for all applications in order to constantly meet the best yarn quality parameters and, at the same time, the highest economic efficiency.

- Ergonomically shaped and robust devices for attaching ring travellers and for maintaining machines to make maintenance work much easier.

Ring/traveller systems for short staple spinning

The key to the success of a ring spinning mill lies in the optimal balance between the conflicting factors of a flawless yarn quality with the simultaneously highest possible productivity of the spinning machine. The optimal selection of spinning rings and ring travellers is crucial here.

The influence of these two spinning components on the yarn quality occurs through:

- Geometry and property of the ring working surface

- Correctly selected ring traveller for the ring profile

- Ring traveller with the correct design of the yarn passage

The following factors are decisive for very high machine productivity:

- Stable lubricant film formation for good sliding behaviour between the spinning ring and ring traveller

- Optimal traveller system on the ring flange for stable operating behaviour

- The lowest variation of ring travellers for gentle handling of the lubrication film

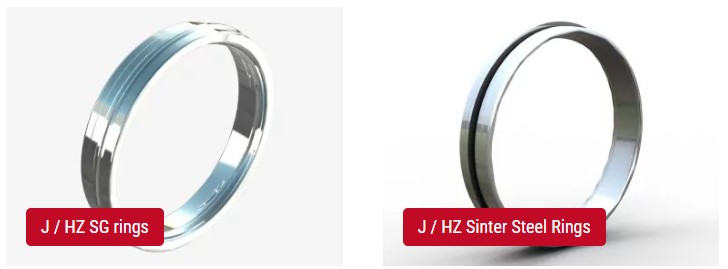

Spinning rings

Reiners + Fürst only uses hardened ball bearing steel of 100Cr6 quality for all rings.

The rings from R+F are manufactured in a LOOP® turning process, tailored to a technological textile application of the rings. The functional surface of the rings is designed with an accuracy that no other turning process offers.

Around the world, R+F is the only manufacturer to produce spinning rings with LOOP ® technology:

- LOOP ® is an R+F development.

- LOOP ® produces spinning rings with the highest precision of the flange structure

- LOOP ® ensures precisely the same surface quality for every single ring.

- LOOP ® guarantees a 100% quality control of the turning process

R+F has the very best prerequisites for continuously improving the ring surface during the turning process. In combination with the constant drive for optimisation, R+F continues to set higher standards, even for the most demanding technological requirements.

R+F offers three different ring qualities for the different applications and operating conditions:

The selection of the appropriate ring quality depends mainly on the yarn programme as well as the achievable spindle speed and the expected service life of the rings and travellers.

All ring qualities are available in the technical versions for all common ring spinning machines:

Ring/traveller systems for long staple spinning / conical and vertical spinning rings

R+F offers the right ring traveller for the entire range – manufactured from the best raw materials and with high shape precision. The surface finish of our ring travellers ensures the best quality parameters from cops to cops of the spun yarns in the complete fineness spectrum. Even at the highest spindle speeds, our travellers maintain a stable position on the ring surface, whereby yarn breakages are reduced to a minimum.

Depending on the application case, you can choose between the following ring traveller qualities:

- SuperPolish

- Hard chrome

- Nylon Steel

Conical and vertical spinning rings

Reiners + Fürst only uses hardened ball bearing steel in the quality 100Cr6 for all ring qualities.

R+F rings are manufactured in a LOOP® turning process, tailored to the technological textile application of the rings. The functional surface of the rings is designed with an accuracy that no other turning process offers.

R+F has the very best prerequisites for continuously improving the ring surface already during the turning process. In combination with the constant drive for optimisation, R+F continues to set higher standards, even for the most demanding technological requirements.

Depending on the application case, you can choose between the following ring qualities:

- J / HZ rings made of steel

- J / HZ rings made of sintered steel

Reiners + Fürst offers tailor-made solutions for your application.

About mezger.

You can put your trust in MEZGER, INC. We provide personal service and exceptional quality. We have been in business for over 40 years. Our unparalleled service, competitive prices, and overall value are why our loyal customers are still with us today.

We look forward to serving you!

We accept major Credit Cards VISA, MASTERCARD and AMERICAN EXPRESS.

- Textile Equipment

- Filtration Equipment

© 2024 Mezger, Inc. site by A-LINE Interactive

Error Message

- phone Call us

- message Request

High quality ring travellers for short staple spinning system

Print this page

Select Your Language

The ring traveller for the pole position

The top seller in the R+F team:

Avus – named after the once fastest German circuit – offers you the speed, durability and yarn quality, which guarantee success in everyday business.

The traveller already shows its strengths during start-up. Immediate, optimum attachment on the ring, and therefore very gentle handling with the lubrication film, is the optimal prerequisite for high-speed spinning and compact spinners. This advantage is maintained throughout the entire service life.

Avus travellers are characterised by

- Optimised start-up behaviour

- Suitability for the highest spindle speeds

- Guarantees the highest wear-resistance

- Constant yarn quality

- Reduction of yarn breaks

The travellers are available in the versions: clip (stored) or loose. Quantity depends on the ISO weight of the traveller.

Please contact us for more information and questions about technical specifications. We are happy to inform you of current R+F developments.

Factsheet Avus

file_download 0 MB

attach_file PDF

info_outline Our fact sheet contains an overview of all facts and figures about this product.

R+F Pocket Book

info_outline General facts and information about our products can be found in our brochure.

Not found your Content? Then search our website

Or call us directly.

The Turbo ring - Fast. Safe. Durable.

The premium class of chrome-plated spinning rings, exclusively at R+F

Thanks to very high manufacturing precision, it combines the best run-in properties, quickly achievable maximum speeds, optimal lubrication film build-up and stable lubrication balance with a long service life.

Reiners + Fürst GmbH u. Co. KG Leibnizstr. 85 41061 Mönchengladbach Germany

Postfach 10 13 40 41013 Mönchengladbach Germany

Phone: +49 (0)2161 934-0 Fax: +49 (0)2161 834-555 E-mail: [email protected]

Privacy | Imprint

- Ring travellers

- J / HZ SG rings

- J / HZ SuperPolish

- SpinCleaner SC 1

- Representatives

- Privacy policy

- General Terms and Conditions

Title Mr. Mrs.

I have taken note of the privacy policy .

Bitte lasse dieses Feld leer.

Spinning Rings - X Optimax Spinning Rings - XL - R Spinning Rings - XL - C Spinning Rings - X Tensa Spinning Rings - X Gen Rings Spinning Rings - Special Sizes Rings Spinning Rings - xl-n Ring Travellers - X Optimax Ring Travellers - xlrs Ring Travellers - xl-cs Ring Travellers - xendowrs Ring Travellers - xendowcs Ring Travellers - Xgen RS Ring Travellers - xgencs Ring Travellers - Jtraveller

- Ring Travellers

- Spinning Rings

- October 20, 2019

The X-Axis with its over 60 years of experience in spinning industry, has been continuously at the forefront of leading technologies that enhances the process of spinning across the globe. Spinners are now realising the importance of choosing the correct Rings and Travellers , as it has a strong bearing on end output. Here in this article we shall look into the functions of Ring and Traveller in Yarn Spinning.

- During the Spinning process the Ring Traveller perform three main task while is running on the profiled surface of the Ring :

- To Provide Twist to the Yarn

- To Wind the Yarn on the bobbin

- To Provide Yarn Tension (Spinning Tension)

- Traveller compensates the variation that arise in the Torsional Force on the fibre strand due to alteration in ration of Delivery of Ring Frame to the Spindle Speed.

- To provide withstanding capacity against the strain generated when the profiled surface of Steel Ring faces extraordinary pressure by the Traveller in motion.

- To limit the heat generation that arise due to friction between Ring and Traveller.

To achieve optimum results for above functions the quality of Ring and Traveller is of utmost importance. The variables that affect the most is Surface Roughness of Ring, Metallurgy, Ring Diameter etc.

The-X Axis is known to produce the best quality of Spinning Rings and Travellers that provides better output and consistency in quality of Yarn as well as optimum performance and longevity of the machine.

More can be known at www.thex-axis.com

Ring Spinning Machine: Drafting System, Different Parts and Functions

Last Updated on 13/12/2020

Ring spinning machine:

This ring spinning was much more productive, simpler in mechanism, easier in manipulation and more economic. This was the origin of ring twisting, probably the most extensively used system for the processes of simultaneously twisting yarn and winding it onto a package.

Functions of ring frame:

- To draft the roving for conversion of very fine strand of some fiber to form yarn of required count.

- To impart strength to the yarn by inserting the necessary amount of twist.

- To collect twisted strand called yarn onto handy and transportable.

Main advantageous features of ring spinning machine:

- Most usable spinning machine in the world.

- Fine to coarse (5-1000 tex) yarn can be produced.

- Yarn has very good strength.

- Yarn is suitable for all next process.

- More than 80% of total yarn is produced by ring spinning machine.

Limitations of ring spinning:

- Low twisting rate

- Low production

- Small bobbin size

- Frequent doffing

- High energy consumption

- Limited speed of traveller.

Drafting system:

Drafting system makes important role at yarn quality and performance of the machine. Normally 3 over 3 drafting system is used at ring frame. Total draft, draft distribution and arrangement of drafting system is very important both for yarn quality and machine performance. Total draft, break draft and distribution of draft for different yarn are given below:

Total draft = Break draft or break zone draft X Front zone draft

- Bottom rollers are fluted steel roller.

- Top rollers are rubber roller, which are pivoted at weighting arm can apply pressure 15-25 daN to the bottom roller.

- Apron is a endless synthetic rubber small belt, which guide the drafted fiber.

- Hardness level of top back roller 80°- 85° shore and 63°- 65° shore at top front roller.

Method of applying pressure:

The following way load or weighting is applied at the nip point of bottom roller by top roller.

- Spring loaded

- Pneumatic weighting

- Magnetic weighting

Different parts of ring spinning machine:

- Roving bobbin

- Bobbin holder

- Guide roller

- Drafting arrangement

- Bobbin tube

A brief description of important parts of ring spinning machine:

Spindle is a hollow cylindrical tube, consists of mainly two parts (upper parts bolster) and capable to run high speed. Normally upper part of spindle is taper, which holds ring cop and bolster is fixed to the ring rail by nut. Spindle is driven by tape at the position of whorl. The diameter of whorl is important for high speed.

Lappet consists of thread guide and an arm. This thread guide lead the yarn centrally over the spindle axis and arm fix at lappet rail.

Ballon control ring:

Ballon control ring is a ring, which control or reduces the diameter of yarn ballon at middle position. Actually it divided the ballon into two sub-ballons. Normally yarn ballon is formed during twisting and winding of yarn at ring spinning machine.

Separator is an aluminum or plastic plate, which is placed between the individual spindle to prevent the hurled of broken thread to neighboring yarn making ballon.

This is the renowned ring, so for the frame is named as ring spinning frame. Most commonly carbon steel is used; but different hardened steel is also used. The ring is tough and hard. The range of its surface hardness is between 800-850 vickers. Ring diameter varies 38-54 mm.

Feature of a good ring:

- Exact roundness.

- Best quality raw material.

- Good, but not too high, surface smoothness.

- An even surface.

- Good, even surface hardness, higher than that of the traveller.

- Long operating life.

- Correct relationship between ring and bobbin tube diameters.

- Perfectly horizontal position.

- It should be placed exactly centered relative to the spindle.

This is the tiny key parts of ring spinning frame which travels around the ring at 30-35 m/sec and impart twist to the yarn. The hardness of the running traveler must be within 650-700 vickers. Contact pressure between ring and traveler is up to 35N/mm². Generate high temperature (300-400°C). the mass of traveller is 16-120gm/1000

Feature of a traveller:

- Generate less heat.

- Dissipate heat fastly.

- Have sufficient elasticity for easy insertion and to retain its original shape after insertion.

- Friction between ring and traveller should be minimal.

- It should have excellent wear resistance for longer life.

- Hardness of the traveller should be less than the ring.

Forces acts on ring-traveller:

- Centrifugal

Yarn is wound around ring cop by cop building mechanism. There are approximately 100-200 gm yarn present in every ring cop.

Technical data:

- Spindle per machine = 480 -1016

- Spindle speed = 12,000 – 20, 000 rpm

- Draft = 15- 45

- Yarn count = 1- 120 Ne

- Production (machine/hr) = 22-30 kg

- Ring cop weight = 180 – 250gm

Winding and heat setting:

Winding is the process of transferring yarns from small ring cop to a suitable large package. Yarn faults like thick and thin places, neps, slubs, and foreign materials are removed here by EYC (Electronic yarn cleaner), which increase the quality of yarn. Store and transfer of yarn is easier for package size. 12-18 ring cop are used to build a winding package (cone).

Heat setting or twist setting:

Newly manufactured yarn has low moisture content and it has snarling tendency. Heat setting is a process, by which yarn receives sufficient moisture, twist sets in certain place and reduces snarling tendency. Heat setting is done by steam with temperature of 60°c during 50-60 minute with a pressure of 5 kg/cm². At a time 200-300 packages insert in a heat setting chamber for this purposes. Some yarns are heat set by waxing with wax devices; these are used only for knitted fabric manufacturing .

Yarn cones are packed in paper cartoons 50 kg for export and 45 kg for local market. Yarn hanks (1lb) are packed 50 kg in sacking for local market for hank dyeing.

Draft and production of ring spinning mill (section wise):

Name of various spinning method:

Image courtesy: http://nptel.ac.in

Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. He is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia.

Share this Article!

Related Posts:

4 thoughts on “Ring Spinning Machine: Drafting System, Different Parts and Functions”

well researched and simplified,easy to follow articles with images

Why ring frame machine use in double motor? Please explain it

Great, thank you for simplifying the essential parts of the ring spinning machinery. The addition of images to the blog was a bonus, it made the comprehension easier. Being a part of the same industry, we can easily vouch that ring spinning machineries are extremely important in spinning mills as they are crucial for determining the end quality of yarn. It’s great that you are shedding light on this topic in such an insightful way.

Please full form of EB4 or packing

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Notify me of follow-up comments by email.

Notify me of new posts by email.

Academia.edu no longer supports Internet Explorer.

To browse Academia.edu and the wider internet faster and more securely, please take a few seconds to upgrade your browser .

Enter the email address you signed up with and we'll email you a reset link.

- We're Hiring!

- Help Center

Spinning Series Ring and Traveller

All about the RIngs and Travellers in ring spinning process

Related Papers

Banu Nergis

Ring-spinning accounts for about two third of global long and short staple yarn production. The main reason for the dominance of ring-spinning over other spinning systems is its versatility in terms of yarn linear density and fibre type, and also the superior quality of ring-spun yarns over those produced by other systems. The main disadvantage of the spinning system is the yarn production rate due to limitations in spindle speed (productivity), high power consumption, traveller wear and heat generation and yarn tension [1].

Autex Research Journal

S.M. Ishtiaque

The mechanism of end breakage in ring spinning is a complex phenomenon, and is entirely different from the yarn failure mechanism during a tensile test. In this paper a possible mechanism of end breakage is reported. A statistical model is developed for predicting the likely end breakage rate in ring spinning. The important factors in governing end breaks are the mean yarn strength, yarn strength variation, mean value of the peak spinning tensions and the variation of yarn mass irregularity. Some practical aspects have also been discussed to tackle the problem of when the breakage rate suddenly increases.

Allegri Gabriele

Ring Rolling is an advanced local incremental forming technology to fabricate directly precise seamless ring-shape parts with various dimensions and materials. To produce a high-quality ring different speed laws should be defined: the speed laws of the Idle and Axial rolls must be set to control the ring cross section and the Driver roll angular velocity must be chosen to avoid too high localized deformation on the ring cross section. Usually, in industrial environment, a constant rotation is set for the Driver roll, but this approach does not guarantee a constant ring angular velocity because of its diameter expansion. In particular, the higher is the ring diameter the lower is its angular velocity. The main risk due to this constrain is the generation of a non-uniform ring geometry. An innovative approach is to design a Driver Roll speed law to obtain a constant ring angular velocity. In this paper a FEM approach was followed to investigate the Driver roll speed influence on the Ring Rolling process. Different Driver roll speed laws were tested starting from a model defined in an industrial plant. Results will be analyzed by a geometrical and physical point of view. Abstract Ring Rolling is an advanced local incremental forming technology to fabricate directly precise seamless ring-shape parts with various dimensions and materials. To produce a high-quality ring different speed laws should be defined: the speed laws of the Idle and Axial rolls must be set to control the ring cross section and the Driver roll angular velocity must be chosen to avoid too high localized deformation on the ring cross section. Usually, in industrial environment, a constant rotation is set for the Driver roll, but this approach does not guarantee a constant ring angular velocity because of its diameter expansion. In particular, the higher is the ring diameter the lower is its angular velocity. The main risk due to this constrain is the generation of a non-uniform ring geometry. An innovative approach is to design a Driver Roll speed law to obtain a constant ring angular velocity. In this paper a FEM approach was followed to investigate the Driver roll speed influence on the Ring Rolling process. Different Driver roll speed laws were tested starting from a model defined in an industrial plant. Results will be analyzed by a geometrical and physical point of view.

Advanced Materials Research

Karen Abrinia

A generalized upper bound solution for the deformation of ring in the ring rolling process has been formulated. An admissible velocity field and strain rates are derived from the parametric definition of streamlines in the deformation zone. This new formulation was used to predict the upper bound on power. Minimizing the upper bound power with respect to neutral point position, the neutral point position and the rolling force were determined. Using the theory presented here, the variation of internal, shear, frictional and total powers with respect to ring revolution are discussed. Some of the results obtained from analysis were compared with experimental results.

AUTEX Research …

Sherif Abuelenin

AIP Conference Proceedings

Luca Giorleo

Procedia Engineering

PROCEEDINGS OF THE III INTERNATIONAL CONFERENCE ON ADVANCED TECHNOLOGIES IN MATERIALS SCIENCE, MECHANICAL AND AUTOMATION ENGINEERING: MIP: Engineering-III – 2021

Anvar Xurramov

European Scientific Journal ESJ

Synthesiology English edition

Hirohiko Arai

RELATED PAPERS

Graham Smith

arXiv: Earth and Planetary Astrophysics

Sergei Ipatov

Procedia Structural Integrity

Chiara Passoni

European journal of management

Muhammad Khan

Journal of Comparative Psychology

Michael Beran

gelavizh barzegar

BMC Women's Health

Zahid Pervaiz

UTS Ilmu Negara

MChadziqun Nucha33

JBRA Assisted Reproduction

ria margiana

Clinical Cancer Research

Brenda Sandmaier

American Journal of Psychiatry

Kathleen Pike

Andes Pediatrica

Alfredo García-Alix

Proceedings of XV International Workshop on Neutrino Telescopes — PoS(Neutel 2013)

David Bravo

International Journal of Environmental Research and Public Health

Giovanni Improta

American Journal of Respiratory Cell and Molecular Biology

EP Europace

Gianni Pastore

MARIA ISABEL TAPIA GONZALEZ

Biochemical and Biophysical Research Communications

Yoichi Gondo

International Journal of Applied Pharmaceutics

International Journal of Applied Pharmaceutics (IJAP)

Journal of Multidisciplinary Care

Noshad Ghasemi

Tatiana Gumucio

Microscopy and Microanalysis

Luis Bernardo López Sosa

Imaging Science in Dentistry

Maryam Baharvand

Art Bulletin

Genevieve Warwick

Massachusetts Review

Tatiana Senkevitch

- We're Hiring!

- Help Center

- Find new research papers in:

- Health Sciences

- Earth Sciences

- Cognitive Science

- Mathematics

- Computer Science

- Academia ©2024

- Subscribers

Welcome, Login to your account.

Recover your password.

A password will be e-mailed to you.

- Ring-Spinning

Essential Machinery Used in Ring Spinning: A Comprehensive List

Problems and success factor of ring spinning, arrangement and schemtics of ring spinning, ring spinning process, ring spinning pros and cons, winding machine classification and faults, types of yarn winding, winding calculation and objective, yarn formation systems, energy consumption for spinning machines and compressed air.

[email-subscribers namefield="YES" desc="" group="Public"] -->

Join the Newsletters

- Manmade Fiber

- Natural Fiber

- Open-End Spinning

- Air-Jet Spinning

- Printing/Dyeing

- Merchandizing

- Post-Production

- Pre-Production

- Automotive Textiles

- Eco Textiles

- Geo Textiles

- Home Textiles

- Organic Textiles

- Technical Textiles

704-853-3043

Travellers - bracker.

75-100 words here for SEO about product line using keywords

SHORT STAPLE SPINNING AND TWISTING

C-shaped travellers for T-Flange rings - SFB and SU travellers for oblique flange rings

Characteristics:

- Diffusion treatment with deepened effect

- Special components penetrate the traveller and are active also when traveller wear occurs

Application

- High-speed travellers

- Ring running in and normal use

- All fibre types

- Up to +50% longer life time

- Up to +1000 higher spinning rpms

- Hightech surface coating

- Improved sliding properties

Application:

- Cotton compact and non compact yarns

- Also suitable to MMF

- For high spindle and traveller speeds

- For all yarn counts

Description:

- New coating technology

- Special designed for MMF

Advantages:

- + 50% longer lifetime

- shorter running in period

- Man Made Fibers

- All yarn counts

- Special nickel plating

- High resistance to corrosion

- Good gliding properties

- Chemical fibres and blends

- Difficult environmental conditions

STARLET plus

- Considerably reduces the risk of early groove formation

- Upgrade of the well established STARLET coating

- Optimal resistance against corrosion

- Extended traveller service life up to 50% and more

- Constant yarn quality values over the entire extended traveller service life

- Especially recommended for Viscose and CO/CV blends

- For PES and dyed fibres

- Suitable for entire yarn counts range

- Diffusion treatment

- Reduced wear at yarn passage

- Consistent yarn quality

- 50% to 100% longer traveller life then SAPHIR

- at high speed

- all fibre types

- Ceramic coating

- Extremely wear resistant

- Over 1‘000 hours traveller life

- For compact spinning

- Highest speed possible

LONG STAPLE SPINNING AND TWISTING

Steel Travellers for conical and vertical rings

- Spinning of worsted and semi worsted yarns - medium to fine counts

- Twisting and draw twisting - fine counts

Nylon travellers for conical and vertical rings

- Spinning and twisting with NYLTEX travellers for heavier counts

- Glassfiber twisting with NYLTEX travellers

- Flax spinning with NYLTEX travellers

- Spinning and twisting with STEELTEX travellers for abrasive materials

Heatherlock Textiles, Inc

2219 east ozark ave, gastonia, north carolina 28054, monday - friday, 8am to 4pm est.

- Airborne Weapons

- Airlift and Tanker

- Combat Aircraft

- Special Missions Aircraft

- Training Aircraft

- Unmanned Aerial Vehicles

- More Air Power

- Appointment

- Soldier Equipment

- Special Operations Forces

- Unmanned Ground Vehicles

- Weapons and Munitions

- More Land Forces

- Aircraft Carriers

- Corvettes and OPVs

- Fast Attack Crafts

- Frigates and Destroyers

- Naval Weapons

- Unmanned Surface/Underwater Vehicles

- More Sea Power

- EW In Depth Articles

- EW Press Releases

- EW Newsletter

- Special – Electronic Warfare – Volume 2 – December 2023

- Special Volume 1 – Electronic Warfare – May 2023

- MilCom In Depth Articles

- MilCom Podcast

- MilCom Press Releases

- Special Volume – Communications – October/November 2023

- Supplement – Tactical Radios – 2022

- Supplement – Tactical Radios – October/November 2021

- Supplement – Tactical Radios – October/November 2020

- Artificial Intelligence

- Compendium – SOF – February/March 2020

- Ukraine Conflict

- Upcoming Events

- 2024 Event News

- AOC Europe 2023

- Army Aviation Mission Solutions Summit 2023

- Paris Air Show 2023

- Euronaval 2022

- Eurosatory 2022

- Farnborough 2022

- Indo Defence 2022

- World Defense Show 2022

- Dubai Airshow 2021

- Euronaval 2020

- CANSEC 2019

- Paris Air Show 2019

- Quad-A 2019

- Euronaval 2018

- Eurosatory 2018

- Farnborough Airshow 2018

- Editor-In-Chief Podcast

- Special Volume 2 – Unmanned Systems 2023 – June/July 2023

- Supplement – Unmanned Aerial Vehicles – 2022

- Supplement – UAV – June/July 2021

- Supplement – Middle East Defence – Feb/Mar 2021

- Supplement – UAV – June/July 2020

- Compendium Archives

- Sup 1 – Jun/Jul 22 – UAV

- Sup 2 – Oct/Nov 22 – Tactical Radios – 2022

- Sup 1 – Feb/Mar 21 – Middle East Special

- Sup 2 – Jun/Jul 21 – UAV

- Supp 3 – Oct/Nov 21 – Tactical Radios

- Com 1 – Feb/Mar 20 – Special Operations Forces

- Com 2 – Jun/Jul 20 – UAV

- Com 1 – Jun/Jul 19 – UAV

- Com 2 – Sep 19 – Modern Soldier

- Com 3 – Oct 19 – Tactical Radios

- Com 1 – Apr/May 18 – Military Rotorcraft

- Com 2 – Jun/Jul 18 – Armoured Combat Vehicles

- Com 3 – Jun/Jul 18 – Modern Soldier

- Com 4 – Jun/Jul 18 – Electronic Warfare

- Com 5 – Sep 18 – UAV

- Com 6 – Oct/Nov 18 – Tactical Radios

- Com 1 – April/May 17 – Mega City Wars

- Com 2 – Jun/Jul 17 – Airborne Electronic Warfare

- Com 3 – Sep 17 – Modern Soldier

- Com 4 – Oct/Nov 17 – Tactical Radio

- Com 1 – Feb/Mar 16 – Unmanned Systems

- Com 2 – Apr/May 16 – Special Operations

- Com 3 – Jun/Jul 16 – Modern Soldier

- Com 4 – Aug/Sep 16 – Airborne Electronic Warfare

- Com 5 – Oct/Nov 16 – Tactical Radio

- Magazine Archives

- Overview Archives

- Editorial Calendar 2024

- Media Kit 2024

- Sponsored Content

- From our Correspondents

- Bunker Briefing

- Press Releases

- Industry News

- Photo Galleries

- Editors Viewpoint

- In Depth Analysis

- White Papers

- Digital Magazine – Subscription

- Print Magazine – Subscription

- Subscribe FAQ

- Testimonials

- Banner Specifications – 2024

- Newsletter Specifications – 2024

- Native content Specifications – 2024

- Advertise with us

- Privacy policy

- Electronic Warfare

- Land Warfare

Russian IADS Redux Part-7: The Effectors

In the next part of our series on Russia’s strategic integrated air defence system, we look at the kinetic ground-based air defence systems it deploys.

In part-6 of our series on Russia’s strategic Integrated Air Defence System (IADS) we examined the command and control architecture it depends upon. The IADS’ role is ultimately to provide a response to air threats approaching or entering Russian airspace. In Russian air defence doctrine this response is provided using kinetic and/or electronic effects.

The kinetic side of the IADS depends on the Russian Aerospace Force’s (RASF’s) fighters and Surface-to-Air Missile (SAM) systems. Sources have shared with Armada that both the fighter and SAM force would be deployed in wartime to protect key Russian strategic targets. Typically, these could include politico-military targets like the Kremlin, the seat of the Russian government in Moscow. Other potential strategic targets include hardened facilities believed to be earmarked for use by the Russian leadership in wartime. One of these facilities is thought to be located at Mount Yamantau, southwest Russia. A back-up facility may exist at Mount Kosvinsky Kaman, western Russia. Russia’s industrial city of Elektrostal, on the eastern outskirts of Moscow, was one of the first locations where the RASF deployed its S-400 (NATO reporting name SA-21 Growler) high-altitude, long-range SAM systems in 2010.

The SAM Systems

Moscow itself is ring-fenced by the RASF’s 53T6 (ABM-3 Gazelle) anti-ballistic missile system. The 53T6 employs SAMs equipped with a ten kiloton (one kiloton is equal to 1,000 tonnes of conventional explosive) nuclear warhead. These missiles would detonate at altitude in proximity to incoming salvos of ballistic missile warheads or formations of hostile aircraft. The logic is that this ‘shotgun’ approach will vaporise, or at least badly damage, these targets.

The S-400 is the mainstay of the RASF SAM force. A typical S-400 battalion includes two batteries. A battery comprises between eight and twelve individual launch vehicles, each equipped with four missile tubes. Thus, an S-400 regiment could have between 56 and 84 individual missiles ready to launch if fully loaded. Each battery has a command post, a 91N6 (Big Bird) S-band (2.3 gigahertz/GHz to 2.5GHz/2.7GHz to 3.7GHz) 324 nautical mile/nm (600 kilometre/km) range surveillance and tracking radar. The 91N6 is joined by a 96L6E (Cheese Board) C-band (5.25GHz to 5.925GHz) early warning and target acquisition radar. This radar has a range of up to 162nm (300km). A plethora of SAMs can be launched by the S-400 with an array of engagement ranges from 21.6nm (40km) using the active radar homing 9M96E missile. Engagement ranges can reach up to 216nm (400km) using the 40N6E missile which has a reported engagement altitude of 98,425 feet/ft (30,000 metres/m).

Legacy systems used by the RASF include the S-300PS (SA-10B Grumble-B) and S-300PM (SA-10D/E Grumble) which have subtle differences. An S-300PS battery has three Maz-543 launch vehicles each with four launch tubes. The battery is also equipped with a single 5N63S (Flap Lid-B) X-band (8.5GHz to 10.68GHz) fire control radar. An S-300PM battery has a single 36N6E (Flap Lid) X-band/Ku-band (13.4GHz to 14GHz/15.7GHz to 17.7GHz) fire control radar with a 162nm (300km) range. Joining the 36N6E is a 76N6 (Clam Shell) X-band (8.5GHz to 10.68GHz) search and track radar with a 70nm (120km) range. The rest of the battery is comprised of up to eight Kraz-260 launch vehicles each with four tubes. Both the S-300PS/PM are thought to deploy 48N6/E SAMs which have a reported 81nm (150km) range. The S-300PS/PM’s 5V55R missile has an engagement range of up to 48.6nm (90km).

Sources have shared with Armada that RASF SAM batteries are not routinely deployed but may deploy from time-to-time to support exercises or training. The batteries would only be deployed in anger to protect key strategic targets like those discussed above. The sources continued that the task of the SAM units is to provide a protective ‘bubble’ above these targets. Air defence coverage up to 54 nautical miles/nm (100 kilometres/km) altitude and a range radius of 189nm (350km) around the target would be provided. The SAM units would work to attrit any incoming air attack as much as possible. Russian air defence doctrine focuses on safeguarding as many strategic targets as possible in anticipation of an eventual counterattack.

One crucial part of the RASF’s SAM force is its 96K6 Pantsir-S1 (SA-22 Greyhound) combined medium-range SAM and anti-aircraft artillery systems. 96K6 units would deploy with S-300 and S-400 batteries. Their role would be to destroy air-launched weapons like anti-radiation missiles or attack helicopters engaging the batteries Armada’s sources added.

Over the longer term, the RASF is looking to introduce new SAM systems to enhance the strategic IADS in the form of the S-350E and S-500 Prometey long-range, high-altitude SAM systems. The S-350E is mooted as a replacement for the RASF’s S-300PS/PM batteries. Open sources state that a S-350E battery has one 50N6A X-band ground-based air surveillance radar with a range of 215nm (400km). The 50N6A is joined by a single 50K6A mobile command post and up to eight 50P6 launch vehicles. Each launch vehicle can fire 9M96/E or 9M100 SAMs with engagement ranges and altitudes of up to 65nm (120km) and 98,000ft (30,000m) respectively. It was reported in January 2020 that the first S-350E battery had entered service, although a developmental system may have been deployed to support Russia’s military presence in Syria. The VKS could receive twelve S-350E batteries by 2027.

The S-500 is mooted to have a longer engagement range than the S-350E. The S-500 ensemble includes a 91N6A(M) air surveillance and battle management radar. This radar is an enhanced version of the 91N6A radar accompanying the S-400. The S-500’s 96L6TSP target acquisition radar is an enhanced variant of the S-400’s 96L6E. These two systems are accompanied by the 76T6 multimode fire control radar, itself thought to be a derivative of the 92N6. Also forming part of the S-500 ensemble is the 77T6 anti-ballistic missile engagement radar the capabilities of which remain largely unknown in the public domain.

Open sources say that missiles equipping the S-500 could hit targets at ranges of up to 270nm (500km). Russian sources have claimed that the S-500 could engage targets at up to 656,168ft (200,000m) altitude. Russian media, seldom the most reliable source, claim that the first S-500 regiment went on combat duty in October 2021.

The long-term prognosis for the S-500 and S-350E systems remains uncertain. As documented by the Royal United Services Institute, a London-based thinktank, the Russian defence industry is dependent on clandestinely-sourced Western microelectronics for sophisticated weapons systems. Will Western efforts to clamp down on Russia’s access to such technology have an impact on the fortunes of the S-350E and S-500?

Stay tuned for more analysis on Russia’s strategic air defence capabilities in the next instalment of our Russian IADS Redux series.

by Dr. Thomas Withington

Read our other Russian IADS Redux articles:

- Russian IADS Redux Part-1: Resonating with Resonance

- Russian IADS Redux Part-2: Hilltop View

- Russian IADS Redux Part-3: Strategic Skywatchers

- Russian IADS Redux Part-4: Missing Link

- Russian IADS Redux Part-5: Reset Password?

- Russian IADS Redux Part-6: Fundament-alists

Sign up to our Electronic Warfare Newsletter:

Related articles more from author, brazilian navy and embraer sign innovation partnership agreement, us marines contract for acv-recovery vehicle, forward-deployed destroyers bring continued euro-atlantic experience for usn, highlight of the month, flex force enterprises, a leader in integrated air and missile defense, asp accurate on-the-move firing, galvion marks first shipment of caiman ballistic helmets to nato through..., aimpoint – a long time supplier of sighting systems to military..., recent articles, royal navy reiterates strategic importance of undersea battlespace to uk, japan’s sdf to evaluate mission master unmanned ground vehicles.

Book Hotels in Elektrostal

Wander wisely with the travelocity price match guarantee.

Cabins, apartments, houseboats! We offer comfortable & private vacation rentals

Save an extra 10% or more on select hotels with Member Discounts

Access exclusive hotel deals, only with the Travelocity app

Check hotel availability in Elektrostal

Elektrostal Hotel & Travel Guide

Travelocity's Russia hotels database doesn't list any place to sleep in Elektrostal.

When you and your family plan to book Travelocity-listed hotels near this region of Russia, Moscow could be an ideal alternative. It can be located 35 miles (54 kilometers) from Elektrostal. Moscow hotels and apartments include he The Ritz-Carlton, Moscow and Ararat Park Hyatt Moscow .

Once you and your family have got to know Elektrostal, why not explore a little more of the area? The Central Russia district has myriad things to offer visitors. Discover Central Russia's old towns and don't forget to see the region's forests, rivers, canals and mountains. In this corner of Russia adventurous travelers might partake in ice skating and four-wheel driving.

35 miles (59 kilometers) to the west of Elektrostal you will find Garden Ring, where you can spend a little time at the Arena CSKA. Khoroshevskiy rooms include the Kutuzovsky prospekt II and Hotel Bega . If you're looking for an alternative, you can visit Garden Ring, 35 miles (53 kilometers) west of Elektrostal. While you are in Garden Ring, take the time to explore the State Literary Museum. The Hotel Savoy Moscow and Hotel Metropol Moscow are great places to retire for the night.

While in town, don't miss out on enjoying thrills and spills in the company of fellow supporters at an engaging game. Luzhniki Stadium can be found 35 miles (58 kilometers) to the west of Elektrostal. Book a Travelocity-listed hotel right in the thick of the sporting action at the Moscow Suites Noviy Arbat or the LikeHome Apartments Arbat .

Before you and your traveling partner journey to Elektrostal, make sure you browse Travelocity's Elektrostal city guide where you can hear local secrets about the numerous attractions on offer.

Elektrostal hotels essential information

Frequently asked questions, hotels near….

- Vnukovo Intl. Airport Hotels

- Sheremetyevo Airport Hotels

- Domodedovo Intl. Airport Hotels

Areas of Elektrostal

- Northern Europe Hotels

- Eastern Europe Hotels

- Lyubertsy Hotels

- Balashikha Hotels

- Ramenskoye Hotels

- Noginsk Hotels

- Kosherovo Hotels

- Zheleznodorozhny Hotels

- Shchelkovo Hotels

- Zhukovsky Hotels

- Ogudnevskoe Hotels

- Central Russia Hotels

- Fryazevo Hotels

- Istomkino Hotels

- Peshkovo Hotels

- Imeni Vorovskogo Hotels

- Berezka Hotels

- Afonasovo Pervoye Hotels

- Bol'shoye Bun'kovo Hotels

- Pavlovskiy Posad Hotels

- Bol'shiye Dvory Hotels

- Kolontayevo Hotels

- Obukhovo Hotels

- Zhilino Hotels

- Kuznetsy Hotels

- Noginskiy Rayon Hotels

- Kudinovo Hotels

- Burelomka Hotels

- Mar'ino-3 Hotels

- Brazunovo Hotels

- Elektrougli Hotels

- Monino Hotels

- Staraya Kupavna Hotels

- Gzhel' Hotels

- Mishchukovo Hotels

- Pashukovo Hotels

- Voskresenskoye Hotels

- Donino Hotels

- Losino-Petrovsky Hotels

- Byvalino Hotels

Most popular

IMAGES

VIDEO

COMMENTS

Rings and travellers are the dominant elements in the ring-spinning process. Key to success is the reduction of the friction coefficient to the lowest level possible. At this point you will get the perfect balanced spinning geometry - that means the spinning tension is on a constant balanced level. The reduction of friction will be achieved ...

The ring guides the traveler in a circular path around the bobbin. Therefore the traveler is constantly changing direction or else it would fly off in a straight path tangential to the ring. This creates a force called centrifugal force. The constant changing of direction of the traveler by the ring causes friction between the ring and the ...

Ring travelers for short-staple spinning. The best performance can only be reached using the best traveler. With various shapes, wire cross-section, weights and finishes, Bräcker's travelers cover any requirements, even the most challenging ones. Explore.

Ring travelers for long-staple spinning. Made of first grade materials, Bräcker's travelers for long-staple spinning showcase excellent running characteristics, resulting in longer lifetime and higher productivity. Registers a unique ID. Is used to generate statistical data that allow the analysis of user behavior on the website.

Ring Travelers for Short-Staple Spinning. Decisive for a perfect quality of the spun yarn. High productivity. Maximum production consistency. Optimum running characteristics. Universal applicability. As one of the key components in ring and compact spinning, Bräcker offers travelers in various shapes and finishes to fit any requirements.

Ring traveller: Ring traveller is the most tinny and simple mechanical element in ring frame. It has a direct effect on the quality of yarn produced as their action physically turns the raw material into finished product. So, ring traveller plays very important role in ring spinning system. Fig: Ring traveller

Ring/traveller systems for long staple spinning / conical and vertical spinning rings. R+F offers the right ring traveller for the entire range - manufactured from the best raw materials and with high shape precision. The surface finish of our ring travellers ensures the best quality parameters from cops to cops of the spun yarns in the ...

For all ring traveller qualities, Reiners + Fürst only uses high-alloyed and wear-resistant steel wire, specifically produced for this purpose. The operational behaviour of ring travellers is essentially determined by the fibre lubrication film formation and therefore by the sliding behaviour between the spinning ring and ring traveller.

Advanced ring travellers for compact spinning which results in high quality compact yarn with lesser yarn breakage. New generation rings & ring traveller for short & long staple spinning application. Ring travellers are used in textile to process yarn.

Ring spinning is a spindle-based method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, ... 6 Traveller 7 Rings 8 Thread on bobbin. A ring frame was constructed from cast iron, and later pressed steel.

Ring travellers for conical and vertical spinning rings. R+F offers the right ring traveller for the entire range - manufactured from the best raw materials and with high shape precision. The surface finish of our ring travellers ensures the best quality parameters from cops to cops of the spun yarns in the complete fineness spectrum.

The traveller already shows its strengths during start-up. Immediate, optimum attachment on the ring, and therefore very gentle handling with the lubrication film, is the optimal prerequisite for high-speed spinning and compact spinners. This advantage is maintained throughout the entire service life.

Here in this article we shall look into the functions of Ring and Traveller in Yarn Spinning. During the Spinning process the Ring Traveller perform three main task while is running on the profiled surface of the Ring : To Provide Twist to the Yarn. To Wind the Yarn on the bobbin. To Provide Yarn Tension (Spinning Tension)

This is the tiny key parts of ring spinning frame which travels around the ring at 30-35 m/sec and impart twist to the yarn. The hardness of the running traveler must be within 650-700 vickers. Contact pressure between ring and traveler is up to 35N/mm². Generate high temperature (300-400°C). the mass of traveller is 16-120gm/1000

Traveller • In ring spinning, the energy to drive the twisting mechanism is derived from the bobbin, but the level of twist is controlled by the traveler. • Each revolution of the traveler inserts one turn of twist into the yarn. • The mass of the traveler has to be balanced against the yarn linear density, and the so-called 'traveler ...

Arrangement and Schemtics of Ring Spinning. Textile School Mar 13, 2012 1. The traveller speed in a ring frame is the main limitation in achieving higher spindle speed because of the frictional resistance of traveller over the ring flange. The design, metallurgy, surface finish and breaking-in of the rings decide….

Spindle Speed 18000 18500 19000. (rpm) Ring DIA. & Flange 38 mm & 3.2 mm. During pilot study in spinning mills, 5/O traveller was found suitab le to spin 34 S Ne, 7/O for 38 S Ne, 8/O. traveller ...

The finite element method was used to model the temperatures of the ring and the traveler for different spinning parameters. The experimental ring temperature and maximum traveler temperature from the validated model were recorded based on the experimental design. The results show that spindle speed, traveler weight and yarn count had a ...

Spinning Rings; Travellers; Spindles; Pressers; Twist Caps; Flyers; About Us; Contact Us; 704-853-3043. Travellers. Travellers - Bracker. 75-100 words here for SEO about product line using keywords. SHORT STAPLE SPINNING AND TWISTING. C-shaped travellers for T-Flange rings - SFB and SU travellers for oblique flange rings. SAPHIR. Characteristics:

Drive • 1h 3m. Drive from Elektrostal to Moscow 58.6 km. RUB 450 - RUB 700. Quickest way to get there Cheapest option Distance between.

The kinetic side of the IADS depends on the Russian Aerospace Force's (RASF's) fighters and Surface-to-Air Missile (SAM) systems. Sources have shared with Armada that both the fighter and SAM force would be deployed in wartime to protect key Russian strategic targets. Typically, these could include politico-military targets like the Kremlin, the seat of the Russian government in Moscow.

Looking for hotels in Elektrostal? Enjoy stress-free travel, with 24/7 Social Support, FREE cancellation on select hotels & Price Match Guarantee.

Elektrostal is a city in Moscow Oblast, Russia, located 58 kilometers east of Moscow. Elektrostal has about 158,000 residents. Mapcarta, the open map.

Lost wedding rings led to a sweet memory for this newlywed couple in Playa Del Carmen, Mexico.

It sits along the Ring of Fire, a 25,000-mile (40,000-kilometer) arc of seismic fault lines around the Pacific Ocean. ... Travel Outdoors Pets CNN Store Coupons About CNN Coupons ...